Sometimes as good

as new is better

The industry’s first circular system that will prolong the life of products up to 100 years.

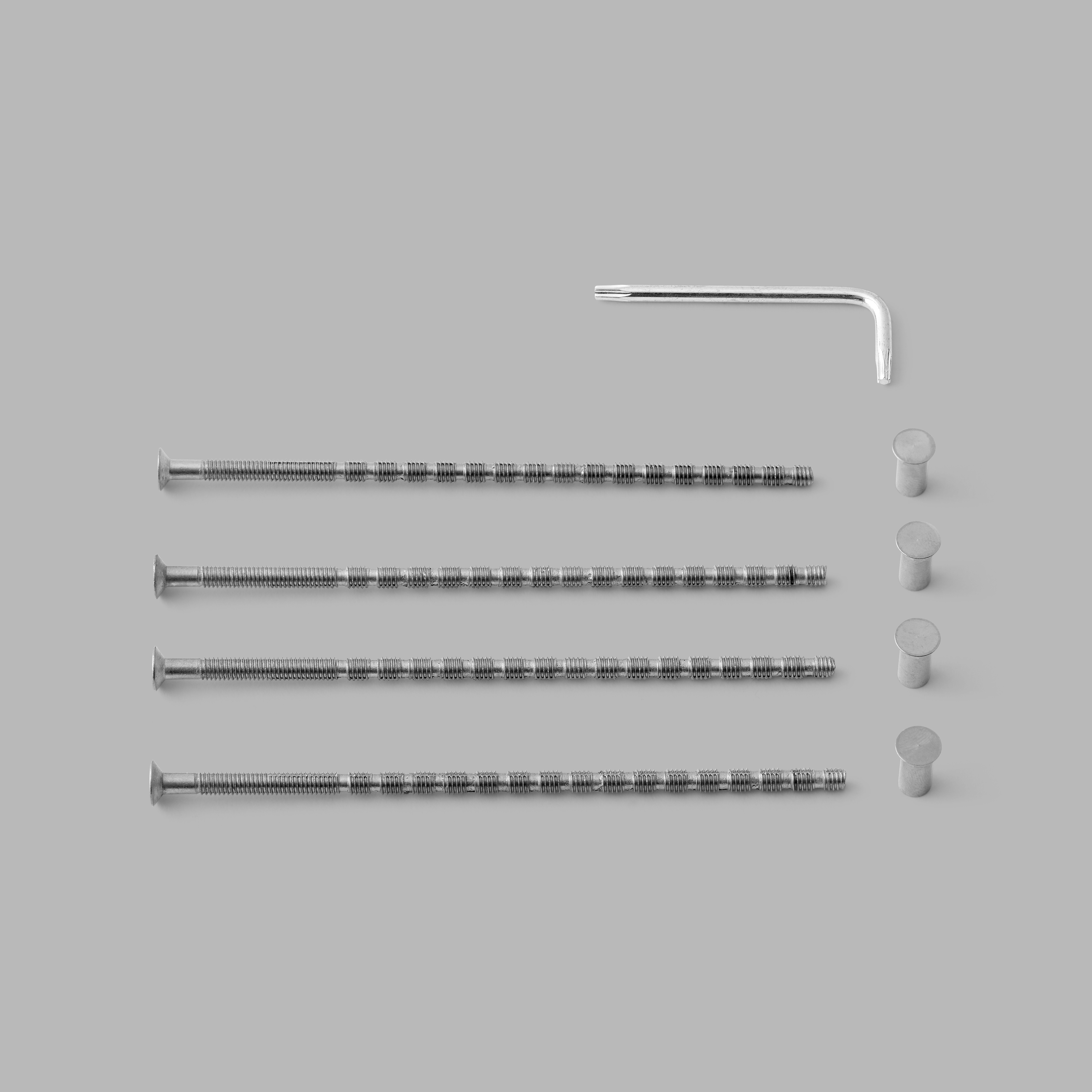

Re-handle by d line is the industry’s first circular service. With the service, we extend the life of our products by replacing parts, repairing, and polishing – so they work and look as good as new.

We exist to lead our industry in sustainability

by acting with care and producing responsibly.

– Over 250 products can be Re-handled.

– Lead time: 8 weeks.

– Any quantity can be refurbished, provided it is environmentally responsible.

– Outside of the 250 Re-handle products, we will evaluate any Re-handle enquiry regardless of product or product age.

Curious about our Re-handle concept? download the brochure to learn more.

Nearly 63% of our carbon footprint comes from our choice of material. We use stainless steel for its hygiene, durability, and timeless look. But it’s resource intensive to produce. Re-handle is our solution.

It’s an easy decision: Repair instead of replacing.

– Up to 100 years of use with four Re-handle services

– Up to 91% CO₂ savings per Re-handle

– Reduced price compared to buying new

We exist to lead our industry in sustainability by acting with care and producing responsibly. The buildings and construction sector are responsible for 37% of global emissions*. At d line, we see this as a responsibility to live our purpose by caring for resources, not only through our Re-handle service, but across everything we do.

In our products:

– 40% of our portfolio comes with EPDs (Environmental Product Declarations).

– 100% recyclable stainless steel taps, showers and bathroom accessories.

– Packaged in recycled and recyclable materials.

In our production:

– In-house facilities with full supply chain control.

– Local sourcing to reduce transportation impact and invest in the local area.

– European Production powered by 100% green electricity.

– 100% of waste carefully sorted and recycled.

– Only 0,3% production failures.

– ISO 14001 certified processes.

– Following the VSME standard for ESG reporting annually since 2024.

* Building Materials and the Climate: Constructing a New Future, date: 2023-09, author: United Nations Environment Programme & Yale Center for Ecosystems + Architecture

At d line obtaining EPD’s and ISO 14001 certifications is a means and not the end of a journey. We think that sustainability is a living thing, so we constantly strive to innovate across design, engineering and technology, seeing our offerings not so much as final results but as continuing evolutions.

Read more about this in our ESG report.